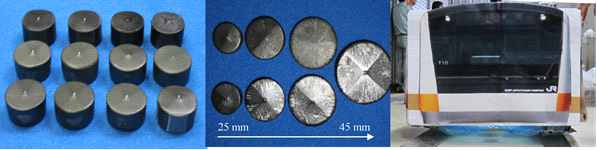

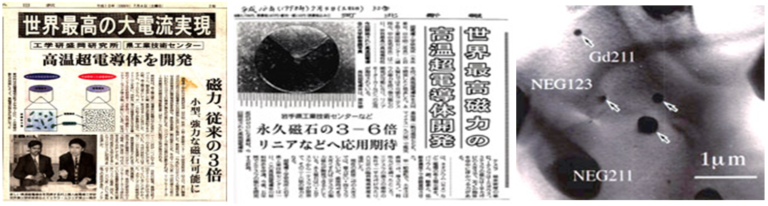

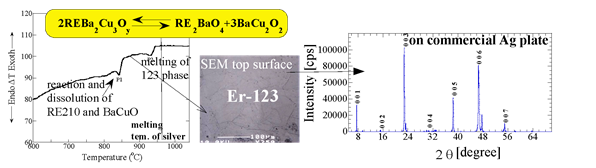

A batch process with cold seeding was developed, which considerably reduces the production cost of various melt-processed LREBa2Cu3Oy (where LRE represents a light rare earth element) compounds. The key prerequisite for the successful batch production are novel thin film Nd-123 seeds grown on MgO crystals, compatible with all LRE-123 materials. It was verified on large Gd-123, Sm-123 and NEG-123 single grains. The samples exhibit a sharp superconducting transition (around 1 K wide) with the onset Tcaround 94 K. The trapped field measurements showed that all the samples in the batch were single-domain and of good pinning performance. The trapped field of nearly 1 and 1.2 T was observed in the best 24 mm single-grain pucks of Gd-123 and NEG-123, respectively. The trapped field in the best 45 mm Gd-123 single-grain pucks reached 1.35 T and 0.35 T at 77 K and 87 K, respectively. The present results prove that a high-performance good-quality LREBa2Cu3Oy material can scale comfortably up from laboratory to industrial production. These results were covered by Japanese patent 2010-244160, Date of filling: October 29, 2010 (Japan).