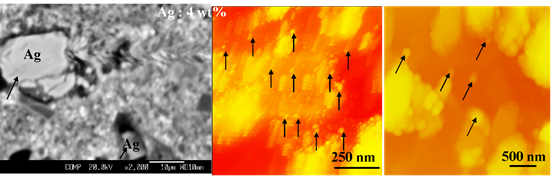

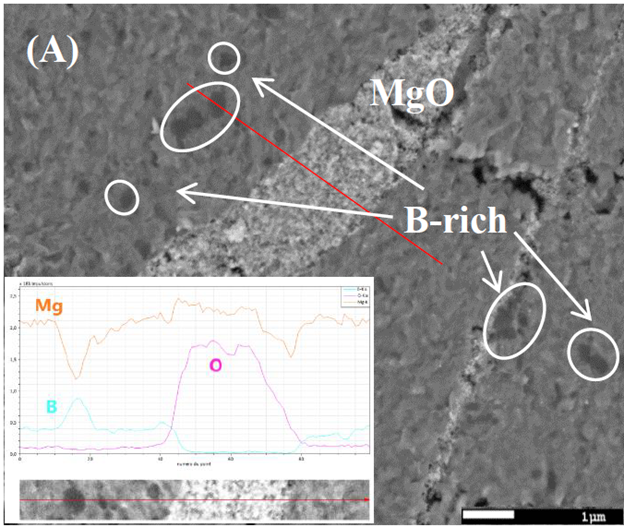

A simple and effective method has been developed to produce high performance and improved mechanical properties of sintered bulk MgB2 materials by adding the optimum silver amount, which is very important for future industrial applications as super-magnets. MgB2 samples with varying Ag contents of 0, 2, 4, 6, 8, and 10 wt% were sintered at 775 °C for 3 h in Ar atmosphere, which was determined previously to be the optimum condition. The Jc values were improved with Ag addition, in that the sample with 4 wt% Ag showed the highest Jc value of 295 kA/cm2 at 20 K and self field. The respective Jc values of the same sample were 430 kA/cm2, 360 kA/cm2 and 238 kA/cm2 in self field, 0.5 T and 1 T at 7 K. These values are the highest so far reported in bulk MgB2 materials. Scanning electron microscopy showed that silver oxide particles are embedded in the voids (see FIG. 9) As a result, the mechanical performance at room temperature was considerably improved with Ag addition. We also confirmed the presence of nanometer-sized AgMg3 particles (see Fig.9 right) which may be responsible for high flux pinning and improved mechanical performances.