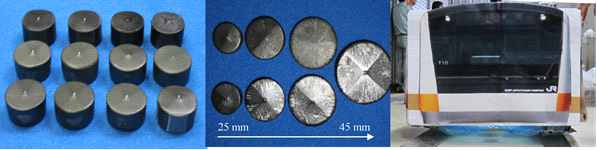

There are numerous environmental impacts of the current transport system, one of the most detrimental being the CO2 emission. Advance technologies are demanded to liberate future generations from this load and enable them to meet their needs. With this vision, we started the national project for the development of the next generation prototype DC superconducting cable for the railway system. The goal of the effort is to develop a feeder of the overhead contact line system between the substation and the electric train. The current and magnetization tests on a two meter long Bi-2223 DC cable sample proved that replacement of the conventional system by the new HTSc cable operating at economical liquid nitrogen temperature is feasible. The inner and outer sheet wires were able to sustain electric currents of 1720 A and 2430 A, respectively, sufficient values for the railways system. The cable performance could be further improved by decreasing temperature from 77 K to 71 K (by lowering pressure above liquid nitrogen). Leaked magnetic field was negligible. The present study confirmed that the new DC superconducting cables satisfy the basic requirements necessary for their use in the next generation railway systems. Eventually, we also successful to produce 30 and 300 meter long Bi-2223 cable and successfully operated the train at RTRI. The critical current (Ic) measurements revealed that the cable conductor layer critical current (Ic) reached 10,130 A while the shield layer Ic was 10,910 A at 77 K. This effort will be followed by the development and manufacturing of a DC cable with lengths of the order of 5 meter up to 300 meters (see in FIG. 8). At the end of the project, the next generation railways are expected to operate climate-friendly DC superconducting cables with the aim of CO2 emission reduction.