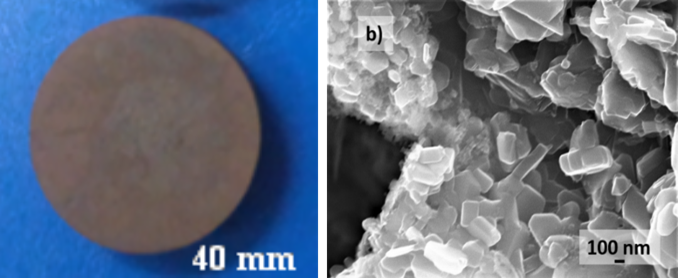

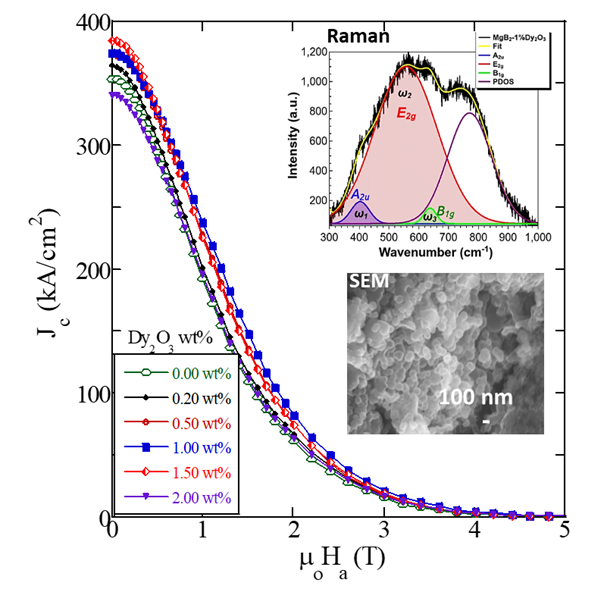

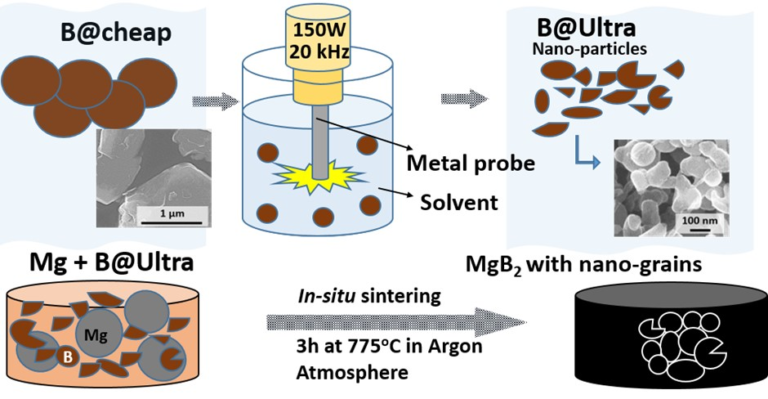

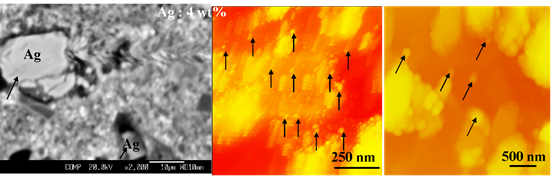

Although magnesium diboride (MgB2) is an interesting superconductor made from abundant materials, increasing its critical current density through easily accessible means has proven challenging. In a recent study, Miryala Lab form Shibaura Institute of Technology, Japan, used ultrasonication to turn cheap commercial boron into a fine nano powder. With it, bulk MgB2 with enhanced superconducting properties can be produced, paving the way to affordable superconducting magnets for medical and transportation applications. The scientists’ synthesis procedure produced high-quality bulk MgB2 mostly free of oxidation impurities. Compared with a non-ultrasonicated sample used as a reference, the Jc values increased by as much as 30%, depending on the ultrasonication time used. Moreover, the results of scanning electron microscopy and energy dispersive X-ray spectroscopy analyses revealed a secondary mechanism that could give rise to enhanced Jc. The team noted a layered structure of what seems to be Mg-B-O coating the walls of pores of boron deficiencies. This layered coating structure can not only act as a pinning center itself, but also have a restraining effect on the grain size.