Superconductors have tremendous appeal in power transmission applications due to their zero resistance. However, to bring classical metallic superconductors into superconducting state requires liquid helium as a coolant, which is costly. Now, scientists from Miryala Lab take things to the new level by demonstrating high temperature superconductivity in mixed rare-earth barium copper oxides fabricated using a popular technique, opening doors to their low-cost, industrial scale production for real-world applications.

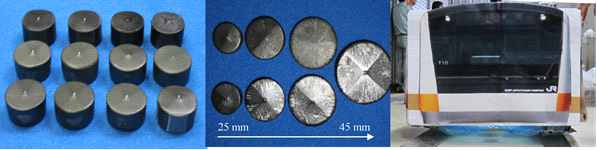

Among the several techniques available for fabricating bulk RE-123, the team went for an infiltrated growth (IG) technique, in which solid (RE)BaCuO5 (RE-211) reacts with a Ba-Cu-O liquid phase to form the superconducting RE-123. Prof. Miryala lays down the motivation behind their approach: “IG technique produces RE-123 bulks without homogeneities, can be performed in air, and scaled up to industrial levels. Moreover, it provides a fertile ground for exploring ternary RE elements systems, which have not been studied until now”.

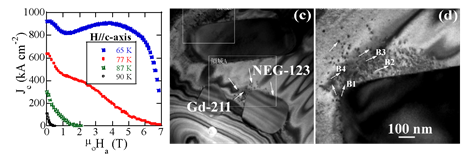

Recently, the team investigated the ternary (Gd0.33Y0.33-xEr0.33+x)-123 bulk system, optimizing its composition by tuning the ratio of Y and Er in the 211 precursor (specifically, x = 0, 0.05, 0.1, 0.15, and 0.2). The XRD proved the single-crystalline nature of the RE-123 bulks, with Tc values in the range (91.5-92) K, significantly above boiling point of liquid nitrogen (77K), and the highest trapped field of 0.61 tesla in (Gd0.33Y0.13Er0.53)-123 (x=0.2) sample with 20 mm in diameter and 7 mm in thick. FESEM and EDX identified finely dispersed (Gd, Y, Er) -211 particles in all samples, with an Er-rich precipitates distribution for x=0.2, the sample which also showed the best superconducting performance.