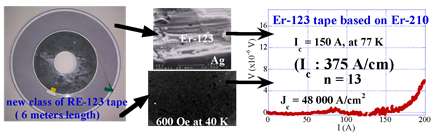

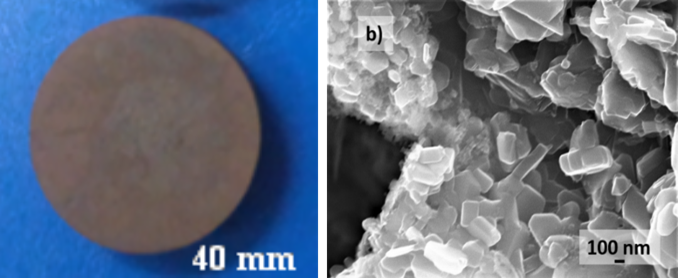

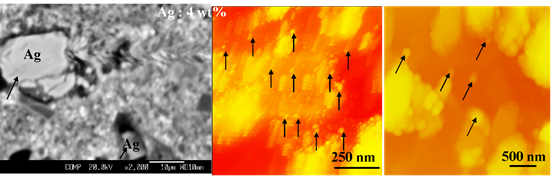

Up to date three types of superconducting tapes have been developed: polycrystalline BiSCCO (the first generation superconducting wires), YBCO thin film (called coated conductor or the second generation superconducting wire), and MgB2, produced in a similar manner as BiSCCO ones. Each of these products faces serious obstacles in achieving satisfactory engineering properties at an acceptable cost. In attempt to overcome some typical problems of the first two wire types, we went a new way and developed technology for a new class of thick Er-123 tapes. We successfully processed good-quality Er-123 tapes with a high crystal quality, density, orientation, grain size, grain coupling, and uniformity. A high transport current was achieved via pre-annealing at around 800 oC, second rolling around 30%, and two-step heating process. Formation of a high-density core before the second heating improved connectivity of the grains and led to formation of a uniform highly oriented Er-123 phase, as confirmed by SEM and TEM analysis. Engineering current Ic close to 150 A (at 77 K and self-field) [375 A/cm] was achieved on a short part of the tape. In the second stage of the development a further improvement of flux pinning is necessary to ascertain safety margins for the high current tape utilization, significantly increase tape homogeneity, and enhance flux pinning at high magnetic fields. A great advantage of the present technology is its capability to produce thick tapes with very good electromagnetic properties. The new processing route opened a way to third generation of coated conductors and to thick RE-123 tapes for power applications.